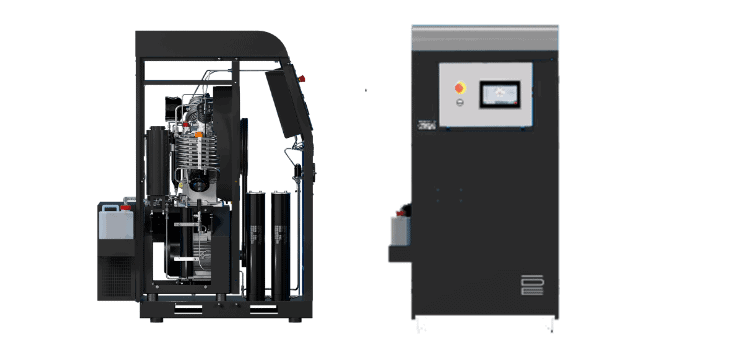

IDE Compressors ist ein Familienunternehmen, dessen Firmengeschichte durch permanente Weiterentwicklung und technologische Kreativität an den Produkten geprägt ist. IDE ist ein erfolgreicher und innovativer Kompressorenhersteller der die strengen Zertifizierungskriterien der ISO 9001, der Druckgeräterichtlinie, und der Betriebssicherheitrichtline erfüllt.

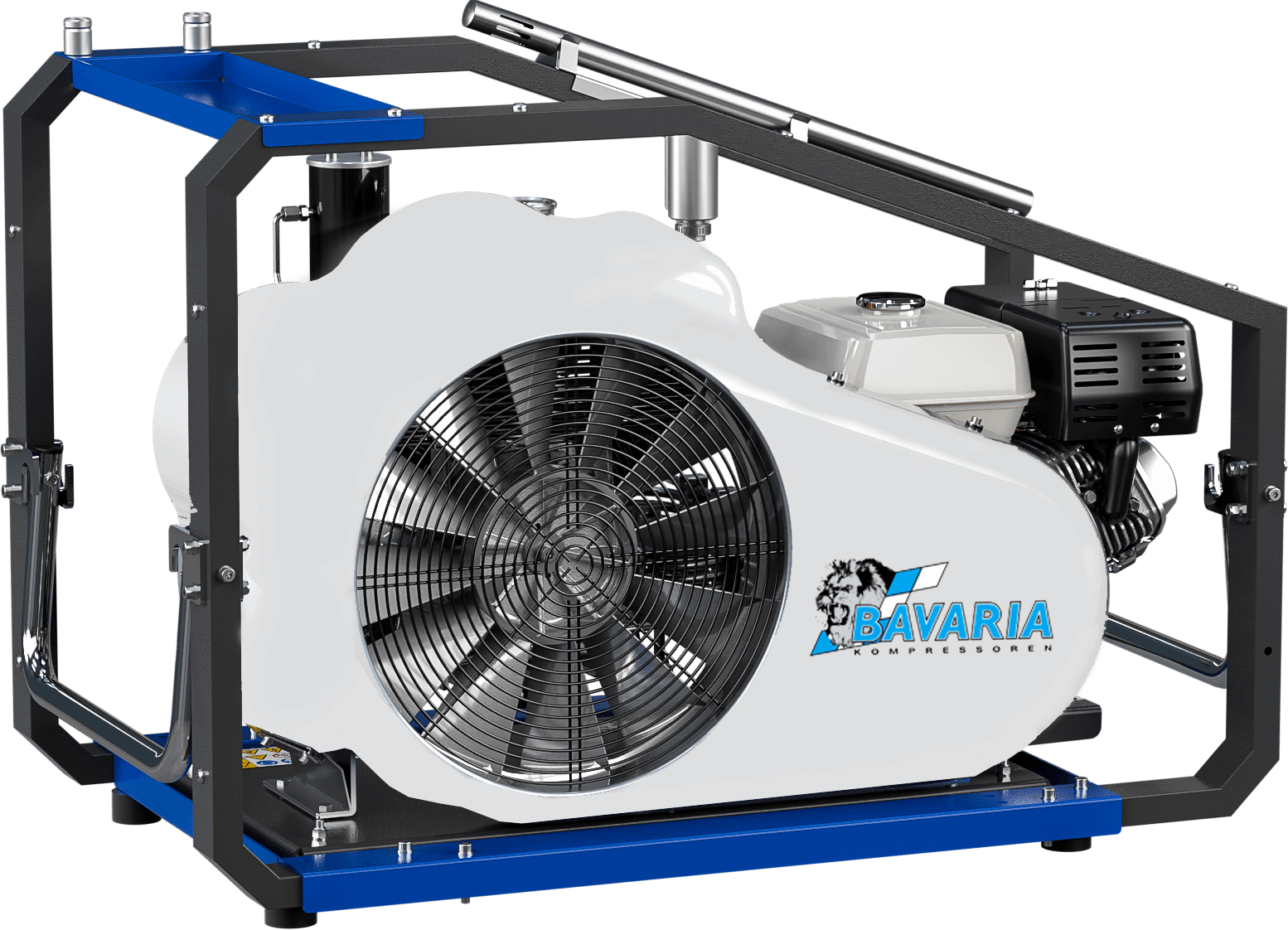

zu Recht wie wir meinen sehen wir unser Unternehmen als "Manufaktur“ steht dieser Begriff doch für weitestgehende Handfertigung, höchste Qualität, großes Forschungs- und Entwicklungspotenzial und Innovation – das begriffliche Gegenteil einer Großserienfertigung.

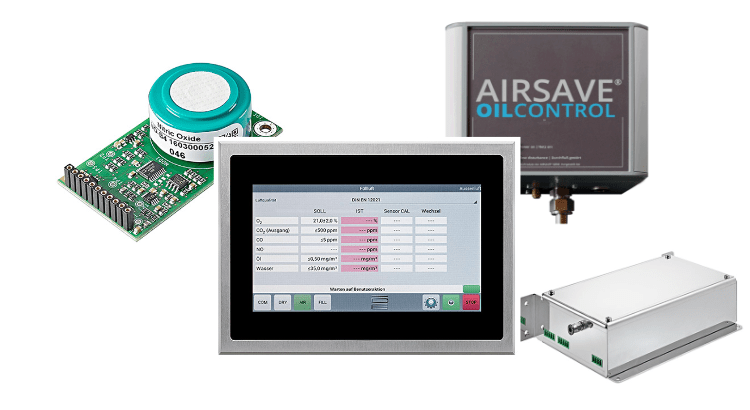

In unserem fertigen wir Produkte für Menschen und Organisationen, die für ihr eingesetztes Kapital das Besondere in höchster Qualität und modernster Technologie wünschen.